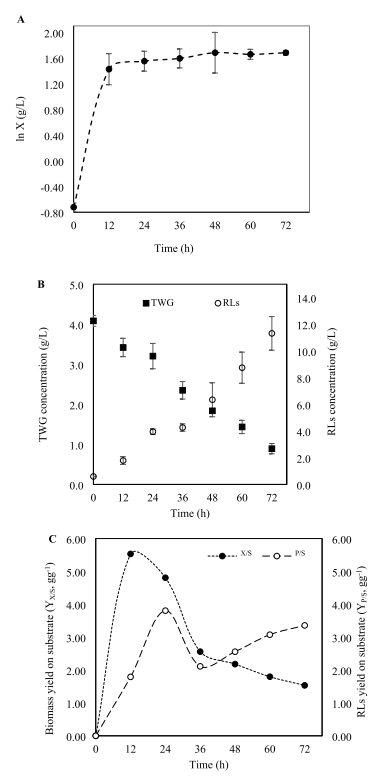

Rhamnolipids (RLs) are glycolipid bio-surfactants produced by microorganisms with applications in industries, including environmental remediation and oil recovery, comparable to chemical surfactants. However, the reproducibility and scalability of RLs production in shake flask systems limit their industrial use, prompting the need for advanced bioreactor systems. This study aims to address this challenge by optimizing RLs production by Pseudomonas aeruginosa RS6 using treated waste glycerol (TWG), a low-cost by-product of biodiesel production, as a carbon source. Response surface methodology (RSM) was employed to evaluate the combined impact of TWG concentration, aeration, and agitation rates on RLs production and microbial behavior within a bioreactor system. Optimal conditions were then determined using central composite design (CCD) and analysis of variance (ANOVA). ANOVA revealed that the quadratic model significantly predicts RLs production (p<0.0001). TWG concentration significantly influences RLs yield (p<0.05), while TWG concentration and agitation rates significantly affect biomass production (p<0.05). Optimal conditions were 2.827% TWG, 1.02 vvm aeration, and 443 rpm agitation. The model's validity was confirmed, yielding 11.32 g/L RLs and 5.38 g/L biomass. Kinetic studies showed YX/S and YP/S values of 5.53 g/g and 3.36 g/g, indicating efficient substrate utilization and metabolite production. RSM optimization enhanced RLs yield by 4.88-fold compared to shake flask results. The produced RLs achieved a kerosene emulsion index of 70.12% and reduced surface tension to 28.61 mN/m, highlighting their potential in environmental remediation. This study addresses the scalability issues in RLs production and highlights the feasibility of using waste glycerol for large-scale RLs production.

Keywords: Pseudomonas aeruginosa · Rhamnolipids · Waste glycerol · Bioreactor · Optimization · Response surface methodology (RSM)

Fig. 1: a) Growth curve of P. aeruginosa RS6 over 72 h of fermentation, b) Change in TWG and RLs concentrations, and c) Trend of biomass yield on the substrate (YX/S) and RLs yield on the substrate (YP/S)

Fig. 2: Crude RLs extracted from the fermentation broth by P. aeruginosa RS6 using TWG as the carbon source

Source: Siti Syazwani Mahamad, Mohd Shamzi Mohamed, Mohd Nazren Radzuan, James Winterburn & Mohd Rafein Zakaria (2025). Optimizing rhamnolipid bio-surfactant production in a bioreactor using waste glycerol. Bioprocess and Biosystems Engineering (2025) 48:1999–2016

Link: https://doi.org/

Date of Input: 30/10/2025 | Updated: 30/10/2025 | ainzubaidah

MEDIA SHARING